Conveyor Belt Tracking and Maintenance Tips

Conveyor Belt Tracking

The conveyor belt is a vital component in manufacturing

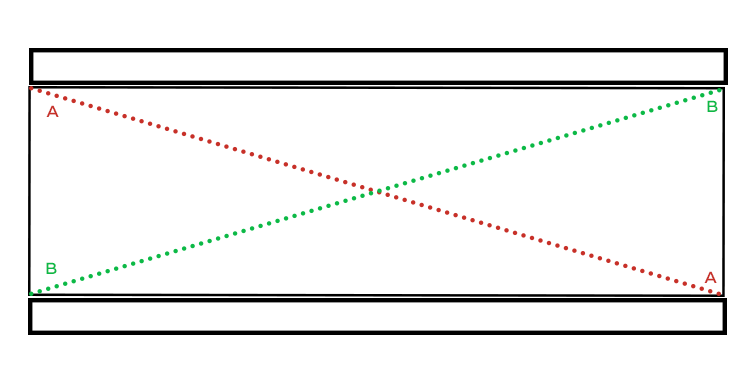

facilities around the world. Almost every product that you see has touched a conveyor belt at some point. The primary job

of a conveyor belt is to transport something from Point A to Point B, typically

in a straight line.

To get the most life possible out of your conveyor belts

proper tracking is vital. Tracking is the practice of adjusting your system to

keep the belt running square along the conveyor frames without rubbing.

If you have any conveyor belts that are rubbing, wandering left/right, or seem to catastrophically fail on a regular basis you may have some tracking issues. Here are a few things to check:

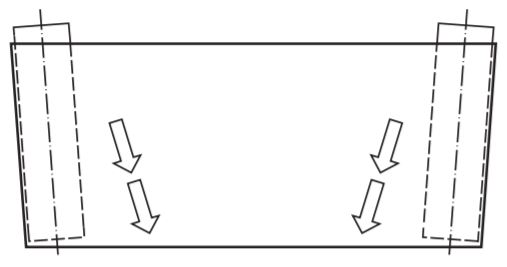

Is your conveyor frame square?

The first thing to check is the overall squareness of your conveyor frame. Checking if your conveyor is square is as simple as measuring from one corner to the opposite corner and comparing the measurement to the opposite side. Depending on the length of the conveyor these measurements may not be exact. You want them as close as possible, but you can accommodate some discrepancy in your head and tail pulley adjustment.

Are your pulleys perpendicular to the frame?

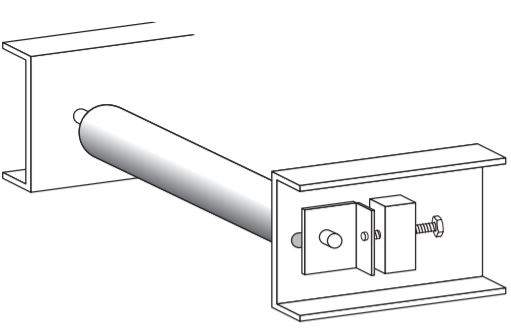

Typically conveyors have adjustments on the tail side of the conveyor (opposite of your gearbox, motor, or other drive setup). The tail often has take-up bearings, threaded slides, or other means of adjusting the way the tail pulley sits in between the conveyor frame. Because of the visibility of the adjustments at the tail, maintenance people typically start here and attempt to “steer” the conveyor from the tail. We recommend starting at the head pulley and confirming the head pulley is perfectly perpendicular to the frame. If it is not you may need to do modifications to the frame, adjust the bearing mounting, or other more in-depth maintenance on the head pulley area of the system.

Once you have confirmed the head pulley, you can do the same checks on the tail pulley. The tail pully is typically set up with some sort of screw, or slide adjustment. Check that the tail pulley is perpendicular and if not use the take up adjustments to correct, keeping in mind proper belt tension needs to be maintained.

It’s still not tracking properly! Now What?

We find that a significant number of belt tracking problems can be solved simply by squaring the frame and the pulleys. If you are still having issues, try the following:

- Check the entire system for product or foreign material in places that is should not be. Inspect the head and tail pulley for product buildup (tape, gloves, or any other material that could wedge itself between a conveyor component and the belt).

- Verify the belt was cut and finished square. If you have a mechanical lace check that the lace runs 90 degrees to the edge of the belt. If it’s not it may need to be cut, replaced, and reinstalled.

- Check the belt is tensioned properly. Both over tensioned and under tensioned belts can create tracking issues.

- For further trouble shooting call your local Baldwin Supply Company sales rep or inside sales office, and we can come on site to look at the application.