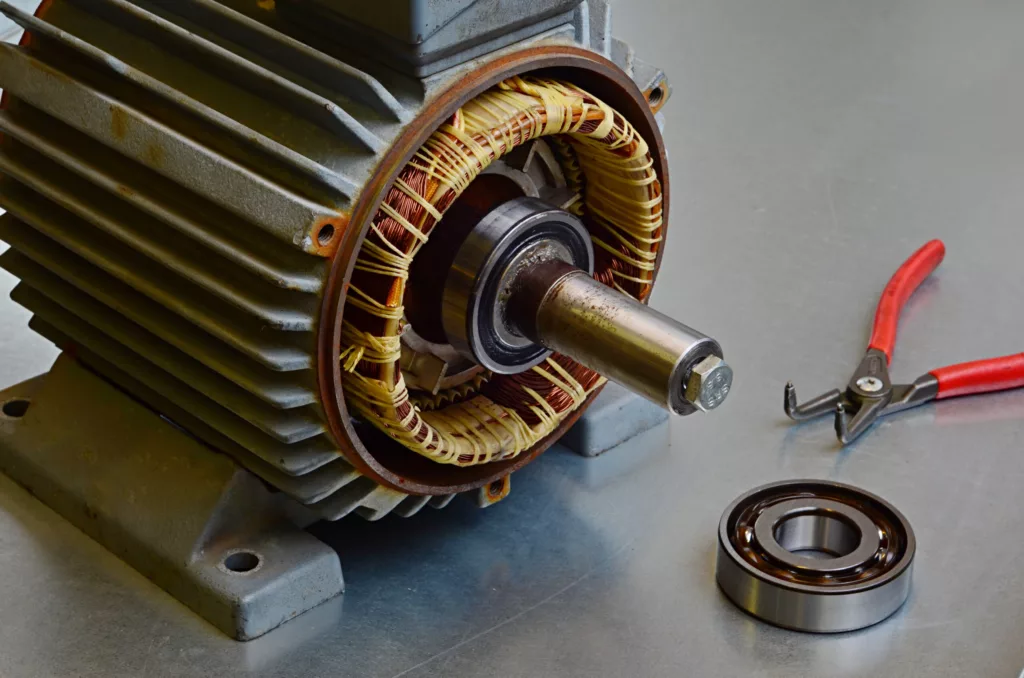

The Importance of Electric Motor Maintenance

Electric motors are the workhorses of industrial processes, powering everything from conveyor belts to pumps, fans, and manufacturing equipment. Their reliable operation is essential for maintaining productivity and minimizing downtime. In this article, we’ll delve into why regular motor maintenance is crucial and how it can significantly impact your operations.

1. Preventive Motor Maintenance

Preventive maintenance aims to anticipate and prevent issues before they disrupt production. By adhering to a well-designed maintenance program, you can ensure that your motors operate reliably. Key aspects of preventive maintenance include:

- Proper ventilation is critical for motor longevity. Overheating due to limited airflow can damage insulation and bearing grease, leading to premature failure.

- Regularly clean dust and dirt from ventilating passages to prevent overheating.

- Consider installing motors in areas with consistent ventilation to maintain optimal operating temperatures.

Predictive maintenance involves monitoring motor performance to detect potential problems before they escalate. Here’s how to implement it effectively:

Monitoring and Data Collection

- Keep a logbook to track historical data on various motor parameters (temperature, vibration, current, etc.).

- Regularly monitor motor operation and compare data to identify trends or anomalies.

- Anticipate issues and schedule maintenance based on observed patterns.

- Develop a proper greasing interval paying close attention to the amount recommended by the manufacturer

- Be sure to use compatible greases, do not mix bases. Most motors utilize a Polyurea base grease but check the motor nameplate to be sure.

When a motor fails unexpectedly, reactive maintenance comes into play. While it’s not ideal, timely repairs are essential to minimize downtime. Key points:

Swift Repairs

- React promptly when a motor fails. Quick repairs prevent prolonged production stoppages.

- Have spare parts on hand to expedite replacements.

- Regularly inspect motors to identify signs of wear or impending failure.

Why Prioritize Motor Maintenance?

Cost Savings:

Unexpected motor breakdowns result in costly downtime. Preventive maintenance reduces the risk of sudden failures, saving both time and money.

Safety: Malfunctioning motors pose safety hazards. Regular inspections ensure safe operation and prevent accidents.

Efficiency:

Well-maintained motors operate efficiently, consuming less energy and reducing operational costs.

Longevity:

Proper care extends motor lifespan, maximizing your investment.

Conclusion

Electric motor maintenance isn’t just about fixing problems—it’s about preventing them. Implement a comprehensive maintenance strategy to keep your motors running smoothly, enhance productivity, and safeguard your operations.

Remember: A well-maintained motor is a reliable motor!